Vasto.FILL

Vasto.FILL is a solution for designers and engineers who need a fast static analysis of how a fuel tank is filled and emptyed at various inclinations. It is a fast, user-friendly, accurate and easy to use tool. Vasto.FILL helps to find the optimal positioning of internal components of a tank, which reduces volumes that cannot be filled and volumes that cannot be emptied. Users can also calibrate fuel level sensors in the tank.

Vasto.FILL differs from its predecessor Fill-Plus-3.0 in the following:

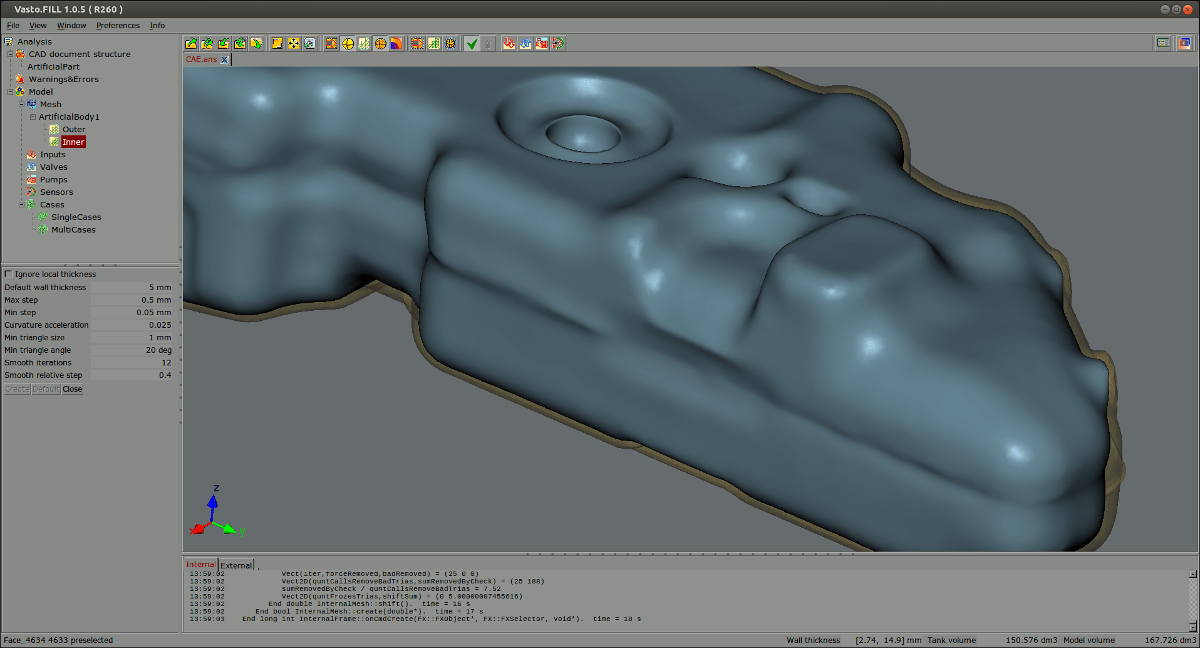

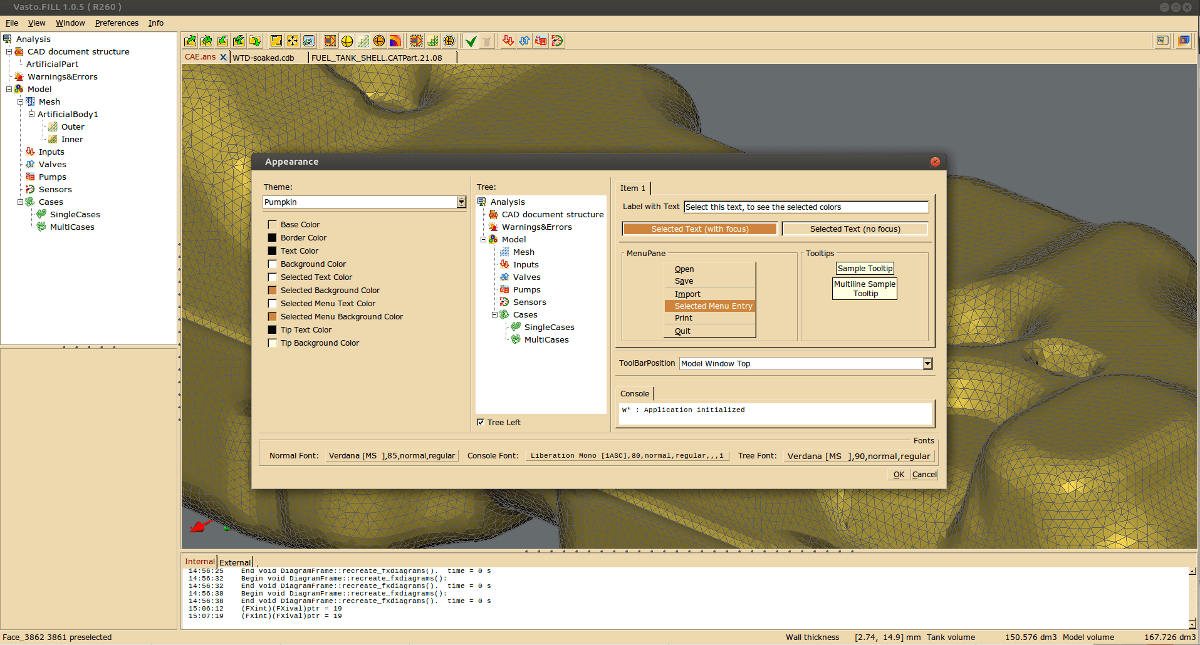

- construction of the real inner surface of a fuel tank with a constant or variable wall thickness

- possibility to import a CAE (not only CAD) model of the external surface of the tank

- lesser use of the computer RAM

- significantly better performance.

The Vasto.FILL package consists of three main modules:

- Vasto.FILL , the main module that provides:

- reading model data and simplification (if necessary) of the outer surface of a tank.

- calculation of the inner surface of the fuel tank

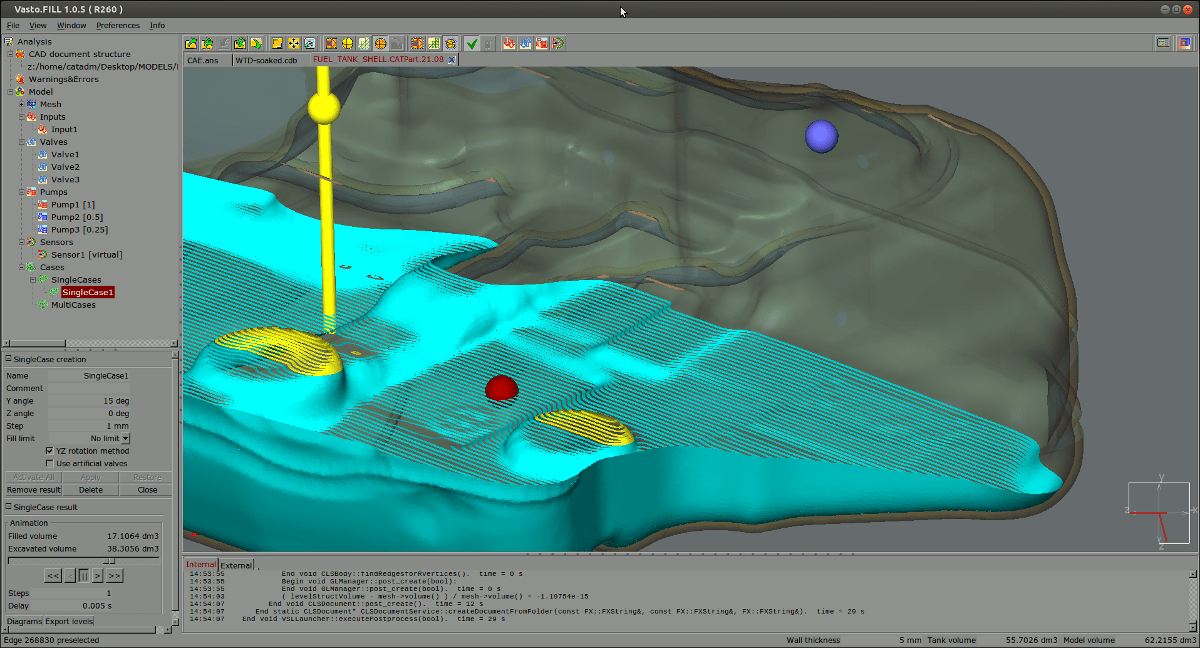

- setting an internal components of the fuel tank: ventilation valves, sensors, and fuel pumps

- setting a calculation cases

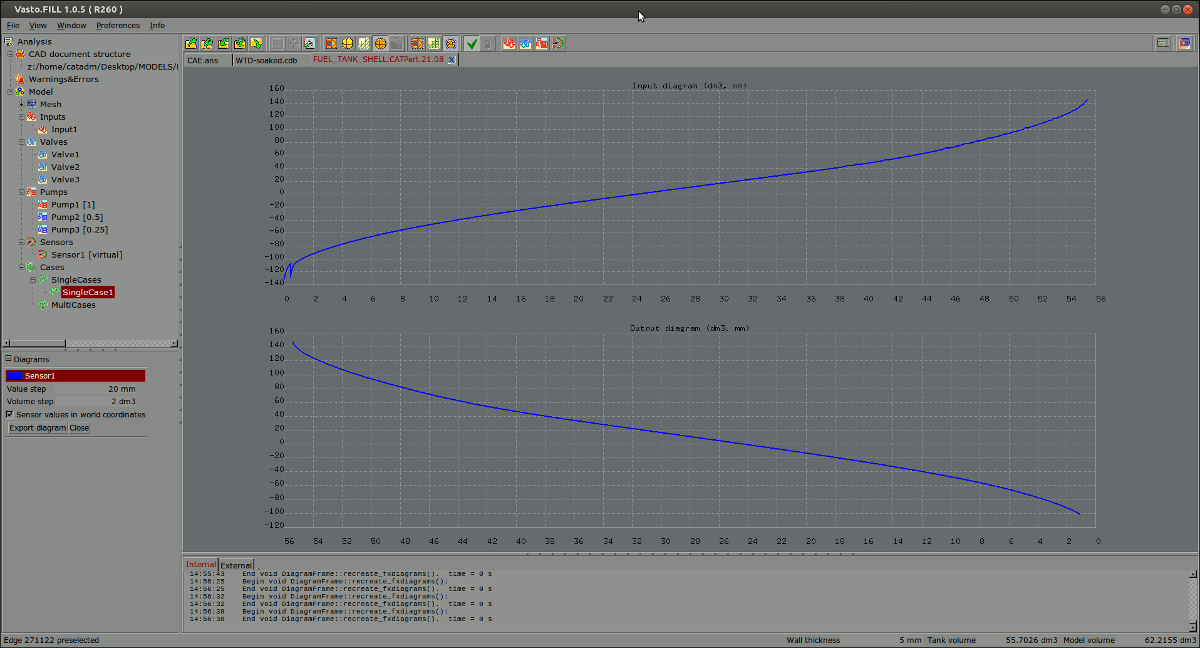

- performing calculations and building diagrams

- visualization of the processes of filling and emptying the fuel tank.

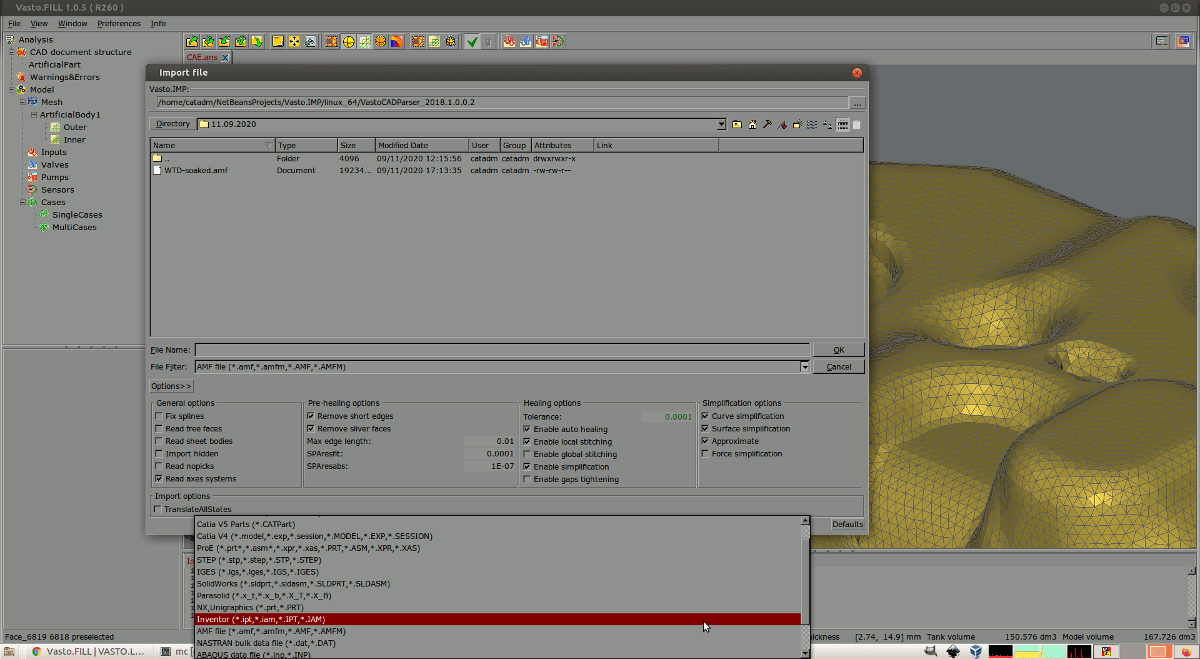

- Vasto.IMP ,the module for importing CAD models to Vasto.OPT. Vasto.IMP is based on InterOp and ACIS Modeler from Spatial Corp and makes it possible to read CATIA, Pro/E, Unigraphics, NX, SolidWorks, Parasolid, STEP, and other CAD models.

- Vasto.CAE2AMF, the module for importing CAE models. It makes it possible to read Abaqus .inp, Ansys .cdb and .ans, Nastran .dat, and STL models.

64-bit operating system:

- Windows 7, Windows 8, Windows 10

- Linux (Redhat/Centos-7/8.x, Fedora-27/28, Ubuntu-14/16/18/20.x, Debian-9.x, Manjaro)

Hardware:

- Intel or AMD 64-bit processor (preferably Intel Core I5 or higher)

- 8Gb RAM (16GB or higher is recommended )

- Graphic card supporting OpenGL 1.0 and higher

We provide our customers with continuous support and grant them access to the bug tracking system. Every bug report is processed in the shortest time possible. Usually it take us just a few working days to resolve the issue reported. Online consulting and trainings are available upon request. Learn more about support